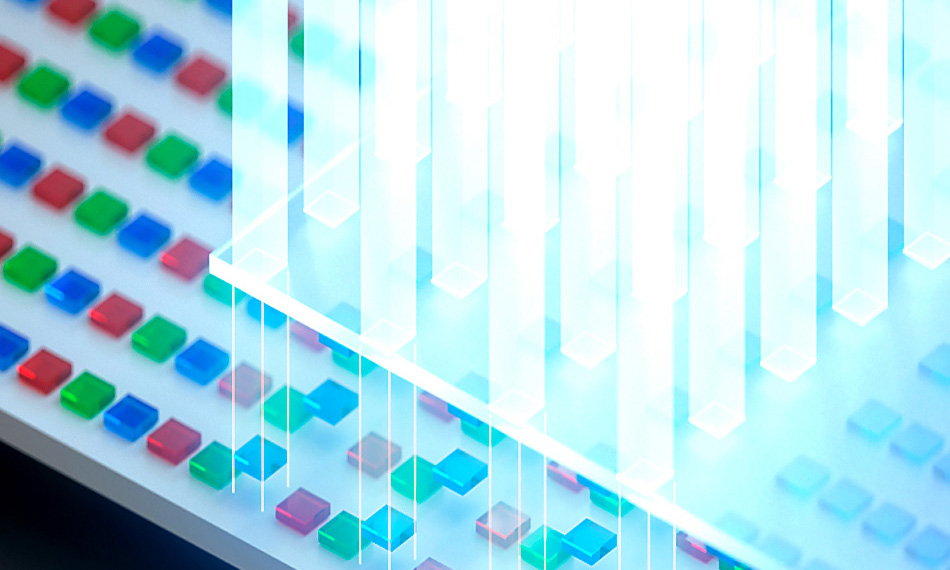

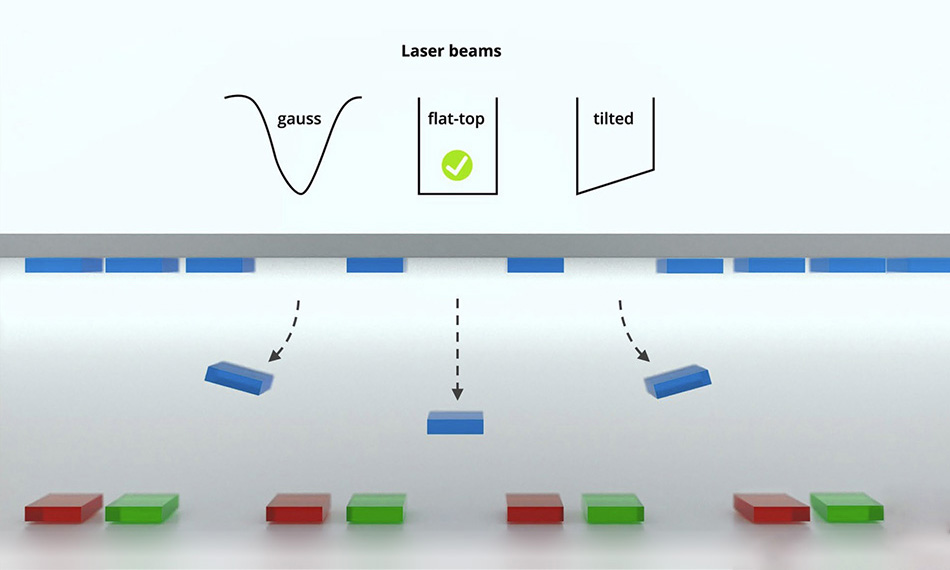

MicroLEDs require new processes and methods even though LED technology has been around for decades and is widely utilized for LCD displays. Bonding and interconnection with the control circuit.End-to-end MicroLED Fabrication ChallengesĬreating MicroLED displays is a multi-phase process that includes some, or all, of the following steps: Recent advancements and developments have helped to move the industry nearer to finally achieving consumer marketability for microLED devices. The timeline for moving microLED displays from research labs to mass production has been slow and is still not complete. Manufacturers must carry out a careful inspection at each step to meet these high expectations, and they must also achieve high yields to ensure production costs remain viable for the mass market. The consumer device marketplace expects near-perfect performance and visual quality from today’s display devices.

To produce these nano-scale elements requires numerous steps, with defects potentially occurring at each one. Yet, manufacturers are still working to close the gap between promise and market reality as establishing a cost-effective fabrication process for microLED displays has proven to be challenging.

MicroLED display-based projectors are built into the latest smart glasses from Vuzix. Vuzix next generation microLED smart glasses teaser Play

0 kommentar(er)

0 kommentar(er)