It misplaces responsibility: Responsibility for quality devolves from the person making the item to the.Production and inspection that any feedback would be meaningless. It is too late: Products have already been made before diagnosis, and often there is sufficient lag between.That inspection does not become a bottleneck in the production system. It is expensive: The system is costly in terms of manpower enough inspectors must be employed to ensure.Significantly, bad product will get shipped to customers. Products will always be rejected or sent for rework due to fatigue, boredom or a dozen other factors.

No matter how good the inspector, some good

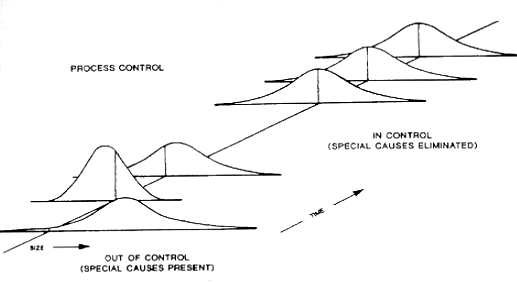

These aspects are properly controlled, in order to deliver the required outcomes.įigure 9.6 reminds us of the generalised process diagram for a process operating on a detection basis introduced in chapter 2.įigure 9.6. Having established what aspects of a process are important to deliver customer satisfaction, it is necessary to ensure that

0 kommentar(er)

0 kommentar(er)